Monitoramento de vazamento de filtro

Detecção de vazamento de filtro: o que é e por que é importante?

Em processos industriais como fabricação de cimento, produção química, energia a partir de resíduos e siderurgia, os filtros de mangas — instalados dentro dos filtros de mangas (baghouses) — são essenciais para remover partículas sólidas do fluxo de gases. Esses sistemas de filtragem desempenham papel fundamental na proteção ambiental, manutenção de condições seguras no trabalho e melhoria da eficiência operacional.

No entanto, instalar filtros de mangas não é suficiente. O monitoramento para detecção de vazamento nesses sistemas é igualmente crítico. Veja por quê.

Conformidade regulatória e segurança do trabalhador

A detecção de vazamento em filtros auxilia as instalações a cumprir normas locais, nacionais e internacionais, como:

- Controle de Substâncias Perigosas para a Saúde (COSHH)

- Lei relativa à saúde e segurança no trabalho

- Diretiva Emissões Industriais (DEI)

- EN 15859 (o que é EN15859)

Com a rigidez crescente dessas regulamentações, os operadores enfrentam pressão para manter o controle das emissões particuladas. Além de proteger os trabalhadores e a comunidade, a não conformidade pode acarretar multas significativas, afetando operações e reputação da empresa.

Evitando a perda de produtos valiosos

Em muitos setores, as partículas coletadas pelos filtros de mangas não são resíduos, mas materiais de alto valor. Como:

- Metais preciosos na mineração e refino

- Ingredientes químicos ativos na produção farmacêutica ou química

- Pós finos usados na fabricação de alimentos e eletrônicos

Se uma manga filtrante apresentar vazamento ou romper, esses materiais podem escapar para a atmosfera, causando perdas financeiras expressivas. A detecção precoce permite a rápida identificação e correção do problema, preservando o produto valioso e evitando desperdícios.

Reduzindo os custos de manutenção e o tempo de inatividade

Filtros de mangas são caros e a substituição demanda mão de obra especializada e tempo. Quando vazamentos são detectados, mas não localizados com precisão, é comum substituir todos os filtros para garantir solução definitiva.

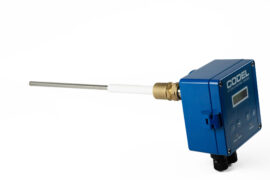

Com o sistema de detecção triboelétrico de vazamento da CODEL, é possível identificar exatamente quais compartimentos ou linhas apresentam problemas. Monitorando tendências durante os ciclos de limpeza e o aumento dos níveis de poeira, o sistema ajuda a localizar rapidamente os pontos críticos. Isso significa:

- Apenas o filtro danificado é substituído

- Menor tempo de manutenção dentro do filtro de mangas

- Redução significativa dos custos de mão de obra e reposição

Qualquer pessoa que tenha passado algum tempo trabalhando dentro de um baghouse entenderá o valor de reduzir o tempo de manutenção sempre que possível!

Apoiando decisões de manutenção mais inteligentes

Os detectores de vazamento de filtro fornecem mais do que apenas alertas básicos. Eles fornecem dados de desempenho contínuos que suportam estratégias de manutenção proativa. Com essas informações, os operadores podem:

- Monitorar a condição do filtro ao longo do tempo

- Detectar sinais precoces de falha antes que surjam problemas graves

- Planejar a manutenção com base no desempenho real do filtro

- Manter um controle consistente de emissões sem depender de suposições

Esse tipo de insight possibilita a transição de uma manutenção reativa para uma abordagem eficiente e orientada por dados.

Conclusão

A detecção de vazamento em filtros de mangas é essencial para qualquer instalação industrial que dependa desses sistemas para controlar emissões. Seja para garantir conformidade, reduzir custos, recuperar produtos valiosos ou melhorar a eficiência, os benefícios do monitoramento são claros.

Os detectores de vazamento da CODEL são confiáveis, projetados para operar em ambientes exigentes e são adotados por diversas indústrias.

Quer saber mais sobre como as soluções CODEL podem ajudar sua planta? Estamos à disposição para auxiliar.