Tribo Dust Monitor & Wireless Connectivity

UK Carbon Black Manufacturing Plant

Главная / О нас / Тематические исследования / Carbon Black Manufacturing Dust Monitoring

The Challenge

This case study describes the successful installation of a new wireless environmental monitoring system.

CODEL International Ltd were approached in 2020 by a major UK Carbon Black manufacturer to provide a more cost-effective service solution for monitoring and reporting emissions to air from their dust collectors.

The customer decided to replace the original monitoring equipment installed with a more user-friendly and cost-effective system capable of providing performance trend analysis for environmental reporting.

The Background

The Carbon Black industry is an inherently dusty business; refractory processing stages generate fine particles that require highly efficient dust collectors to reduce both product loss and the presence of fine particles within the plant.

The Solution

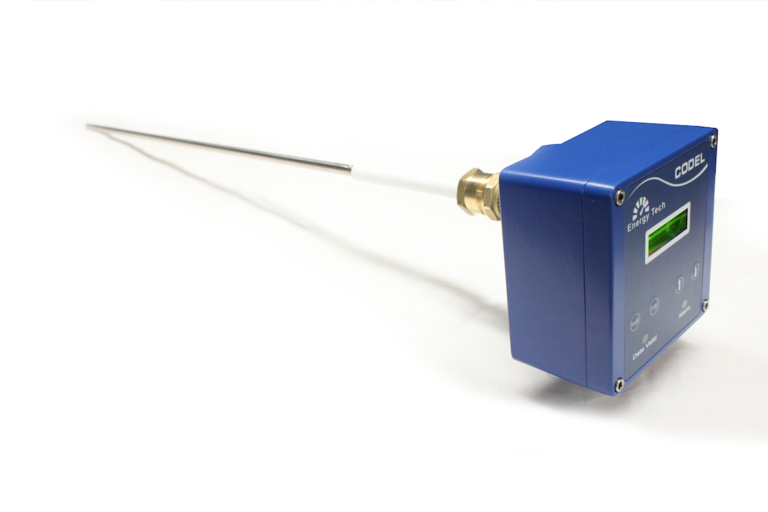

The facility installed the ET301 Dust Monitor and the COMTECH360 wireless GSM technology.

This has reduced the time spent by the company’s environmental department in the preparation of compliance reporting. By interfacing each dust monitor with the COMTECH system, upper management have the capabilities to view the status, historical data and alarm conditions of production areas from their own computer or devices through an online CLOUD based dashboard.

This enables the end user to optimise performance and automate data capture for environmental compliance reporting.

The Result

A new system was seamlessly installed to continue providing emissions levels and critical alarm alerts. The ability to continuously monitor collector performance and events has all but eliminated the need for emergency shutdowns while improving maintenance efficiency.

The decision to move companies was based on a reputation within the industry and a dramatic reduction in service costs.

Commissioning

The Codel UK Service Manager commissioned the system and assisted with start-up.

According to the Engineering Manager the new system has been invaluable in removing the need for an expensive service agreement without any loss of functionality.

Conclusion

Currently the site has two ET301 dust monitors connected to the COMTECH system. The facility plans to “daisy-chain” the system with two further dust monitors into the existing control panel.

The Codel system provided an immediate and significant reduction in service agreement costs and brought emissions monitoring back in-house.

EnergyTech 301 Dust Monitor

EnergyTech 301 — это недорогой монитор пыли, использующий зарекомендовавшую себя трибоэлектрическую технологию, обеспечивающую точные и быстрые результаты. EnergyTech 301 не требует критического выравнивания и не имеет оптических поверхностей, которые необходимо содержать в чистоте. Датчик прост в установке, для него требуется только простой зонд, и он идеально подходит для воздуховодов небольшого размера.

Особенности и преимущества

- Метод прямого зондирования, фактическая концентрация частиц.

- Автоматизированная онлайн проверка нуля и диапазона.

- Встроенная функция калибровки для вывода мг/м3.

- Простая установка и минимальное обслуживание.

- Адаптируемый, подходит практически для всех пылеуловителей.

- Широкий выбор размеров воздуховодов от 250 мм до 2 м.

Download Case Study

Download this case study as a PDF document.

Для получения дополнительной информации о любом из наших продуктов, пожалуйста, заполните форму запроса, и сотрудник ответит вам в кратчайшие сроки.

Вы также можете позвонить по телефону: +44(0)1629 814351