Reduce Operating Expenses Across Your EfW Plant

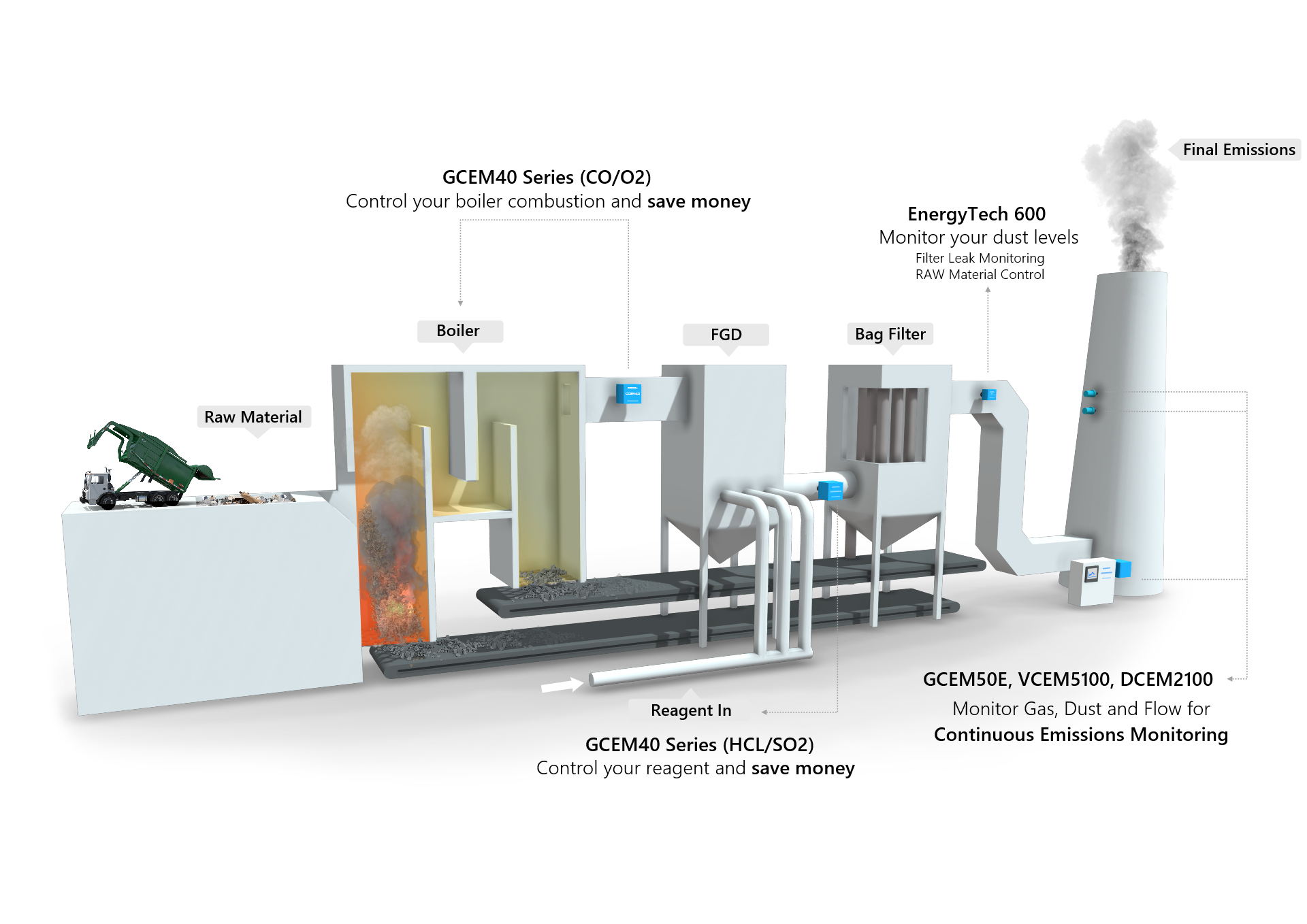

With the cost of reagents and maintenance on the rise, Energy from Waste (EfW) operators are under increasing pressure to control operational expenses while maintaining compliance and uptime. One of the most significant areas for cost reduction is optimising your emissions monitoring strategy – and that’s where CODEL’s GCEM 40 Series comes in.

The True Cost of Inefficient Monitoring

Abatement and reagent costs for EfW plants can reach up to £40 per tonne of waste processed. For a typical UK EfW facility handling 250,000 to 300,000 tonnes per year, that translates to over £3.25 million annually in reagent spend alone.

Poor-quality or poorly suited gas analysers can dramatically inflate this cost. Without precise real-time gas data, operators tend to overdose to stay within compliance – wasting reagents, increasing wear on abatement systems, and risking downtime. Conversely, underdosing can lead to environmental breaches and costly penalties.

Cut Reagent Waste and Improve Accuracy with the GCEM 40

CODEL’s GCEM 40 Series is an in-situ continuous emissions monitoring system (CEMS) designed specifically for the raw gas conditions in EfW plants. It delivers accurate, real-time measurement of HCl, SO₂ and H₂O, directly in the gas stream, with no need for external sample conditioning.

Key benefits of the GCEM 40

- Built-in probe shield protects against harsh raw gas and particulate loading

- Withstands dust loads up to 10 g/m³ – where many analysers clog or fail

- No sampling systems or coolers required, meaning no loss in measurement accuracy

- Minimal maintenance and longer probe lifespan reduce service interventions

- High accuracy enables better control of reagent injection and abatement efficiency

By avoiding overdosing and unnecessary shutdowns, sites using the GCEM 40 are reducing both operational costs and environmental risks.

Real Impact, Proven in the Field

CODEL’s GCEM 40 is already being trusted by multiple EfW operators across the UK, delivering measurable savings:

- Reduces reagent and abatement costs by improving dosing accuracy

- Lower maintenance spend thanks to robust in-situ measurement and fewer part replacements

- Reduced downtime by eliminating failures due to sampling line blockages or cooler faults

These savings compound across the plant lifecycle, contributing significantly to reduced operating expenditure and higher plant availability.

Reducing operational costs in Energy from Waste plants requires smart, reliable technology that delivers long-term value. The GCEM 40 series provides accurate, real-time gas measurements directly from the raw gas stream, helping plants optimise reagent use, cut maintenance demands, and avoid costly downtime. Its robust design performs where other systems struggle, making it a dependable choice for challenging environments. For EfW operators looking to stay compliant while improving efficiency and protecting the bottom line, the GCEM 40 offers a proven solution.

Puedes encontrar las especificaciones completas en la ficha técnica del producto o en el folleto.

Productos adecuados

The GCEM40 Series High Dust analyser is an in-situ device which is cost effective, low maintenance and designed for process control.

CO, NOx, SO2, HCl, CH4, CO2 y H2O

Ficha técnica / Descargar folleto

¿Buscas un manual?

Por favor contáctenos a continuación y estaremos encantados de ayudarle.

Para obtener más información sobre cualquiera de nuestros productos, rellene nuestro formulario de consulta y un miembro del personal le responderá lo antes posible.

También puede llamar al: +44(0)1629 814351