Worldwide Support

Over 25 distributors and support centres worldwide

Flexible maintenance contracts

Tailor made plant specific contracts with 24Hr Support

30 years experience

Developing, manufacturing and installing

Air Flow Monitors in Tunnels

In most tunnels there are ventilation systems installed of which there are three main types:

- Longitudinal ventilation

- Cross ventilation

- Longitudinal & Cross ventilation

Depending on the conditions and the situations encountered in a tunnel, different air speeds and direction are applied and validated by the anemometer. The measurement of the anemometer is then used in a closed loop to control the speed of the fan.

Ventilation in road tunnels has three main objectives:

- To protect users as much as possible in case of a fire in the tunnel

- To limit the pollutant levels within the tunnel under normal operation

- To provide good dispersion conditions for the pollutants

Pollution

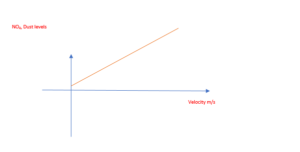

The ventilation enables dilution of the tunnel air by bringing in fresh air. Depending on the level of pollutant concentrations (e.g. NO₂ and dust) the ventilation fan will increase or decrease. The set point is given by the measurement of the anemometer. The polluted air is pushed towards one or the other of the entrances of the tunnel. The direction is confirmed by the anemometer which expresses positive or negative speeds.

The direction is confirmed by the anemometer which expresses positive or negative speeds.

Fire

For each fire position and back pressure, it is important to control the air speed by the control of the ventilation. Again, this is achieved very accurately through the anemometers.

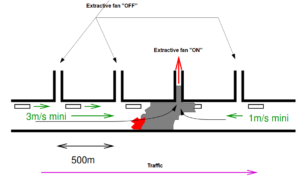

Example:

The violet arrow shows the traffic direction. This means that all cars before the fire are stopped. Additionally, all extractive fans before the fire are turned off. The fan that is on allows the removal of smoke to the exit (red arrow) to protect people. Furthermore, a velocity of 3 m/s ensures that the smoke doesn’t go back to the stopped cars, while the 1 m/s acts as a barrier to the smoke. The above image shows that 3 m/s and 1 m/s are in opposite directions. Therefore, an anemometer is required for both direction and measurement.

Savings

Conclusion

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351