Burst Bag Detection

The purpose of dust burst bag detection

Dust burst bag detection systems are essential for maintaining the efficiency and reliability of baghouse filters, which play a critical role in reducing dust emissions and complying with environmental regulations. These systems quickly detect and address bag failures such as ruptures or leaks, helping to maintain a clean, safe working environment, protect equipment, and prevent hazards associated with dust leakage. In this way, dust burst bag detection is crucial for preserving both environmental integrity and workplace health.

Baghouse Filter System Overview

Baghouse filters use fabric bags to capture dust particles while allowing clean air to pass through. These systems are widely used across industries such as manufacturing, power generation, and dust collection, ensuring that dust is effectively managed, and air quality is maintained.

Dust Burst Bag Detection Systems

These detection systems continuously monitor the condition of filter bags, instantly identifying any breaches or failures. If a bag develops a hole or rupture, dust may escape into the clean air stream, and the detection system will quickly identify the issue, allowing operators to take corrective action.

Alarm and Alert Mechanisms

When a dust burst or leak is detected, the system triggers an alarm or sends an alert to operators. These notifications can be visual, audible, or sent directly to a control room, ensuring immediate awareness of any issues that require attention.

Maintenance and Remedial Actions

After an alert, operators can swiftly inspect the affected bag, repair or replace it, and perform necessary maintenance to prevent further leaks. Regular upkeep and proactive management are key to ensuring optimal performance and longevity of the baghouse filter system, preventing costly downtime and maintaining compliance with environmental standards.

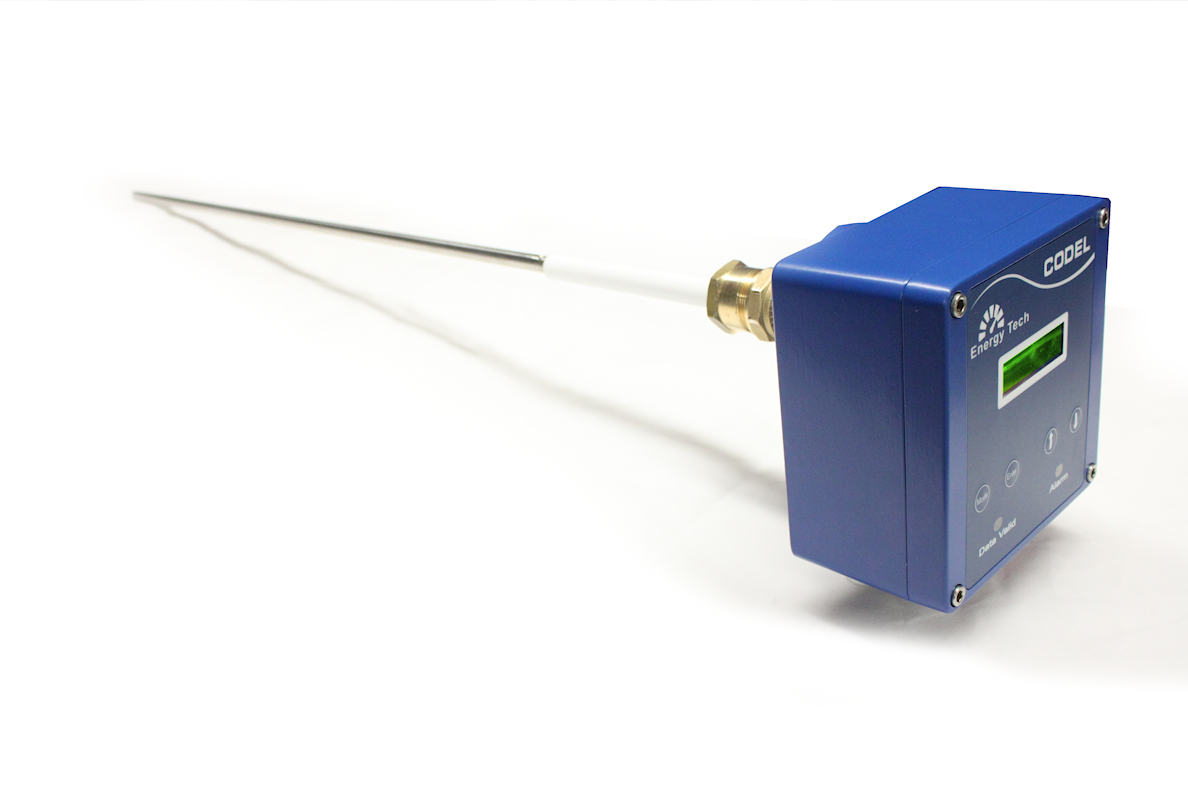

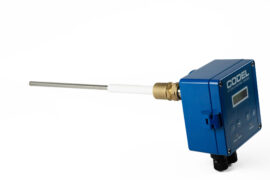

CODEL's Broken Bag Detectors

CODEL’s EnergyTech 600 Series is the ideal solution for broken bag detection in baghouse filter systems. Designed with advanced technology, the EnergyTech 600 Series continuously monitors dust particle emissions, allowing for early detection of any bag ruptures or leaks. With its highly sensitive detection capabilities, it ensures that any breach in the filter bags is promptly identified, enabling operators to take swift action. This helps maintain compliance with environmental standards, reduces downtime, and ensures the smooth operation of industrial processes. The EnergyTech 600 Series is reliable, easy to install, and requires minimal maintenance, making it a perfect fit for efficient dust control.

CODEL Cloud Integration for Remote Monitoring

One of the standout features of CODEL’s EnergyTech 600 Series is its seamless integration with CODEL Cloud, allowing you to monitor the status of your broken bag detectors from anywhere, at any time. With real-time data accessible remotely, operators can stay informed about dust emission levels, receive instant alerts, and track the performance of the EnergyTech 600 Series without needing to be on-site. This enhanced connectivity means you can quickly respond to any issues, ensuring optimal performance and compliance, all while reducing downtime and maintenance costs. CODEL Cloud provides the ultimate solution for efficient, proactive monitoring of your filtration systems.

Suitable Products

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351