The use of Continuous Emission Monitoring Systems in Glass Manufacturing

In the glass manufacturing industry, Continuous Emissions Monitoring Systems (CEMS) are critical for ensuring regulatory compliance. They also help maintain environmentally responsible production.”

Glass production involves high-temperature processes that release significant amounts of pollutants. These include nitrogen oxides (NOx), sulphur oxides (SOx), particulate matter (PM), and volatile organic compounds.

CEMS provide continuous measurement of these emissions. This allows glass manufacturers to track pollutant levels and ensure compliance with environmental regulations.

CEMS monitor key emissions to identify areas where the plant can improve pollution control measures, ultimately reducing its environmental footprint. Additionally, CEMS contribute to improving operational efficiency by enabling manufacturers to fine-tune production processes.

How CODEL Supports Emission Monitoring in Glass Manufacturing

Building on the importance of CEMS, CODEL International Ltd. offers advanced emission monitoring systems. We tailor these systems to meet the specific needs of the glass manufacturing industry. Our CEMS solutions are designed to handle the unique challenges of high-temperature glass production. They provide continuous and accurate measurement of critical pollutants.

Building on the importance of CEMS, CODEL International Ltd. offers advanced emission monitoring systems. We tailor these systems to meet the specific needs of the glass manufacturing industry. Our CEMS solutions are designed to handle the unique challenges of high-temperature glass production. They provide continuous and accurate measurement of critical pollutants.

By integrating CODEL’s systems, glass manufacturers can not only ensure compliance with environmental regulations but also gain valuable insights into their operations, enhancing both sustainability and efficiency. We build our monitors for long-term reliability, helping plants reduce emissions, optimize energy use, and improve their environmental impact. Whether you are looking to upgrade or implement new systems, CODEL’s emission monitoring solutions are perfectly suited to support the evolving needs of the glass manufacturing sector.

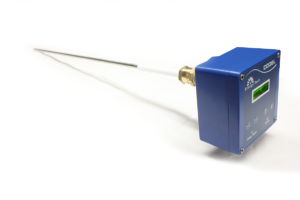

In addition to our core CEMS offerings, the EnergyTech 301 is an ideal solution for dust monitoring within glass manufacturing plants. Utilizing proven triboelectric technology, this low-cost dust monitor delivers accurate and rapid results without the need for complex maintenance. The EnergyTech 301 requires no critical alignment or optical surfaces to clean, making it particularly attractive for small duct sizes and environments where ease of installation is crucial. With minimal maintenance and infrequent probe cleaning, this sensor offers an efficient and cost-effective solution for monitoring dust levels, ensuring that your facility stays compliant with environmental regulations while reducing maintenance overhead.

Suitable Products

The EnergyTech 301 is a low cost tribo electric dust monitor using well-proven technology providing accurate and rapid results.

Dust

A single-pass optical device which uses visible light to measure the opacity and dust within the flue gas.

Opacity / Dust

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351