Tunnel Emission Monitoring

Tunnel Emission Monitoring

Tunnel emission monitoring is a critical process that involves the measurement and assessment of pollutants released into the atmosphere within road tunnels and underground transportation systems. This monitoring is essential for ensuring compliance with air quality standards, evaluating the effectiveness of pollution control measures, and protecting the health and safety of tunnel users and nearby communities.

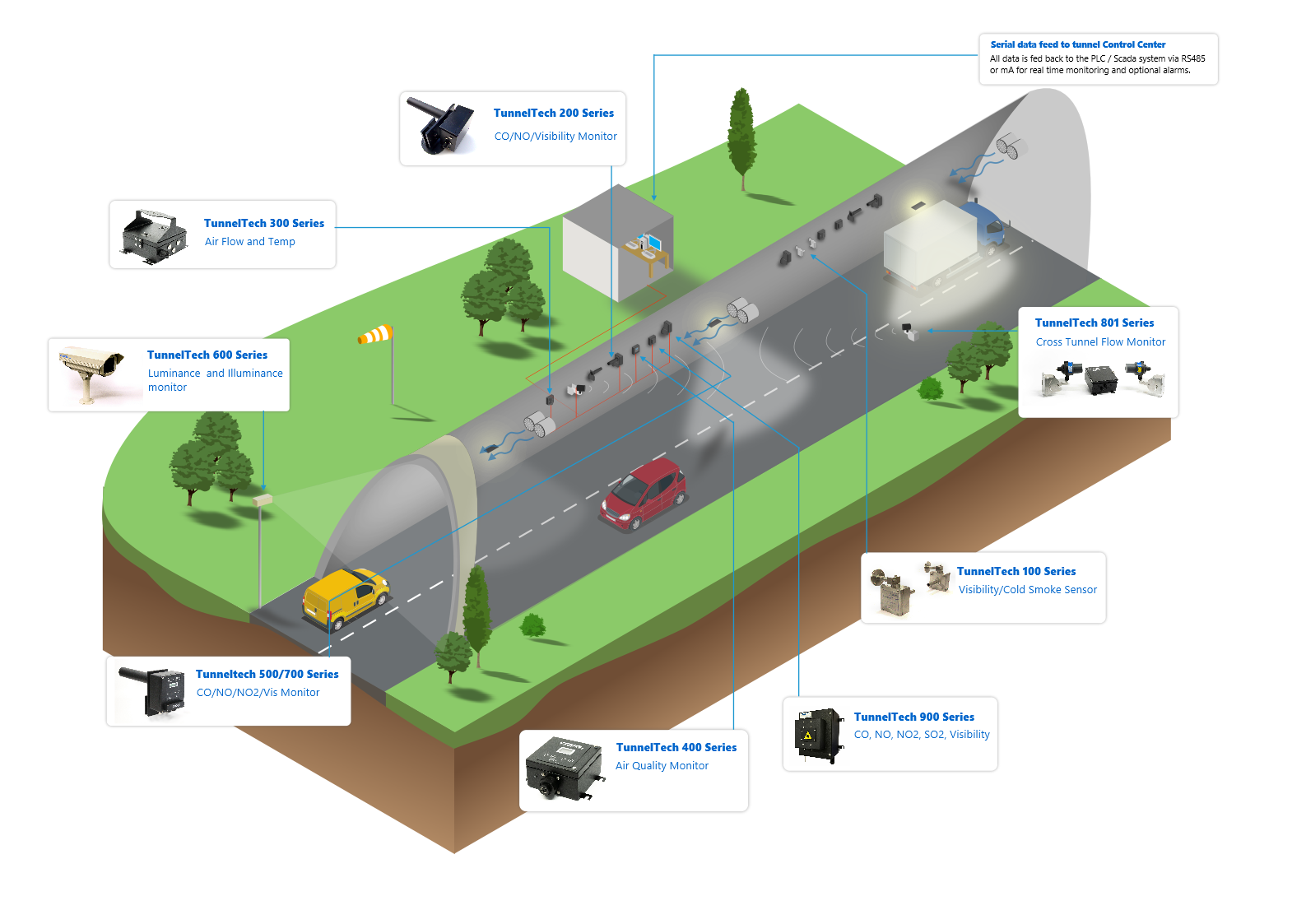

Our Range of Tunnel Monitors Include:

- Visibility Monitors

- Air Quality Monitors (Including CO, NO, NO2)

- Single Point Flow Monitors

- Electrochemical Cell Air Quality Monitors

- Light Monitors

- Cross Tunnel Flow Monitors

Why Monitor Emissions in Tunnels?

Cost Savings

Monitoring emissions in tunnels can lead to significant cost savings by optimizing ventilation system performance. Real-time data allows operators to adjust airflow based on pollution levels, reducing energy consumption and lowering electricity costs. Additionally, emissions monitoring supports predictive maintenance, helping to identify potential equipment issues early and avoid expensive repairs or downtime. By ensuring regulatory compliance, it also prevents costly fines, making it an essential tool for efficient and economical tunnel management.

Environmental Compliance

Regulations governing tunnel emissions are becoming increasingly stringent. Monitoring systems help operators comply with air quality standards by detecting pollutant levels and enabling timely corrective actions. This proactive approach minimizes environmental impact, safeguards public health, and ensures smooth operation without regulatory penalties.

Safety First

Monitoring emissions in tunnels is essential for ensuring the safety of drivers and tunnel users. Pollutants such as carbon monoxide (CO) and nitrogen oxides (NOx), emitted by vehicles, can accumulate in confined spaces, posing serious health risks and reducing visibility. Continuous monitoring allows for the precise regulation of ventilation systems, preventing dangerous pollutant build-up and maintaining safe air quality levels throughout the tunnel.

Why Choose CODEL's Tunnel Emissions Monitors?

Choosing CODEL’s Tunnel Emission Monitors guarantees exceptional accuracy and reliability in monitoring air quality within road and rail tunnels. Built on years of experience and proven technology, our monitors are specifically designed to address the unique challenges of tunnel environments. They provide real-time data to ensure safety, operational efficiency, and compliance with stringent industry standards and regulations. With CODEL’s Tunnel Emission Monitors, you can trust in the precision and durability needed to maintain optimal air quality and protect public health in tunnel applications.

Diagram Download

Looking for a manual?

Please contact us below and we will be happy to help you.

Our Range of Tunnel Products:

TunnelTech 100 visibility monitors are an essential part of any road or rail tunnel safety system. It monitors the Visibility within the tunnel and ensures that the tunnel ventilation system

provides sufficient clean air for drivers to clearly see the road ahead.

The TunnelTech 200 Series Air Quality Monitors can continuously monitor CO, NO & visibility within road and rail tunnels. Monitoring of these vital gases ensures that the tunnel ventilation system provides sufficient clean air to protect tunnel users health and for drivers to clearly see the road ahead.

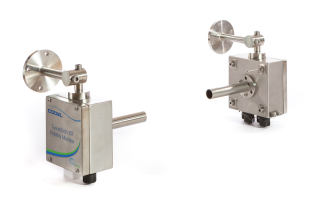

The TunnelTech 300 Series Single Point Air Flow Monitors (AFM) are CODEL’s industry proven tunnel air flow monitors that combine the reliability of ultrasonic technology and delivers superb accuracy and reliability at a very competitive price.

The TunnelTech 500/700 Series use electrochemical cell technology to determine CO, NO & NO2 concentrations within road and rail tunnels. As there are no moving parts, reliability levels are very high and maintenance requirements are low.

The TunnelTech 600 series light monitors are CODEL’s industry proven llumiance and illuminance monitors for detecting light both inside and at the entrance of the tunnel.

The TunnelTech 801 cross flow monitor has been specifically designed for road, rail and civil tunnel and ventilation shaft applications and represents the latest in compact ultrasonic sensor-head design.

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351