Worldwide Support

Over 25 distributors and support centres worldwide

Flexible maintenance contracts

Tailor made plant specific contracts with 24Hr Support

30 years experience

Developing, manufacturing and installing

How well are you controlling NO₂ in your Road Tunnel?

NO₂ Control in Road Tunnels

The need to minimise NO₂ exposure in road tunnels has been inhibited by the lack of suitable, low-maintenance sensors for measuring ppb levels of NO₂ . Recent improvements in technology have resulted in the introduction of not one but two competing techniques designed specifically for this application, making the possible control of tunnel NO₂ levels a reality rather than just a desire.

- NO₂ should now be a key control parameter.

NO₂ is particularly toxic. Levels higher than 1ppm can be harmful to healthy people. Lower levels as low as 0.1ppm will harm asthma sufferers.

- Current ventilation strategies based upon CO and visibility are inadequate.

It is assumed that if safe operating CO levels are maintained then other gaseous emissions will also be safe.

- CO levels are now too low to be an appropriate control parameter.

The introduction of catalytic converters has produced a major reduction in exhaust CO emissions. CO levels in tunnels rarely exceed the ventilation control trigger points.

- NO is not considered to be a harmful pollutant in tunnels.

At concentrations prevalent in tunnels NO is not itself a harmful pollutant and has no purpose as a control parameter. It has been used to infer NO₂ levels in the absence of low cost reliable NO₂ sensors.

- NO₂ cannot be inferred from the measurement of NO.

To infer NO₂ from NO measurements, the ratio of NO₂ /NO is taken to be 1:10. Recent tunnel test data shows that the ratio is actually variable to values greater than 1:3, resulting in serious under reporting of NO₂ values.

- New measurement techniques makes NO₂ a viable parameter for control.

The Codel TunnelTech 205 has been tested and approved by CETU in France for the measurement in the range of 0 to 2ppm in road tunnels. The Codel TunnelTech 205 uses a far simpler Single Wavelength Optical Transmissiometer (SWOT).

Recommendations for NO₂ Limits

World Health Organisation (2005) – Recommends an upper limit of 200μgm/m3 (100ppb) for a 1 hour exposure.

PIARC (2000) – Exposure to levels higher than 500μgm/m3 (250ppb) for 30minutes can impact on the health of sensitive people.

CETU France (Centre d’Etudes du Tunnels) – Following Circulaire 99.239 of 8 Juin 1999 (Ministière de la Santé) the following limits are recommended:

400ppb for 15 minutes – NO₂

50ppm for 30 minutes – CO

90ppm for 15 minutes – CO

NO₂: NO Ratio

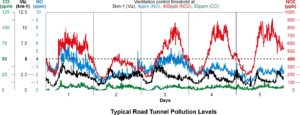

Data from CETU illustrates the importance of NO₂ for ventilation control. Traditional control parameters CO & visibility are significantly below control threshold levels; NO₂ is persistently above the control threshold. The data also shows how the NO₂/NO ratios vary from 1:20 to 1:3. Inferring NO₂ levels from a measurement of NO is not reliable. A direct measurement of NO₂ is essential for control.

Sensor Comparison Data

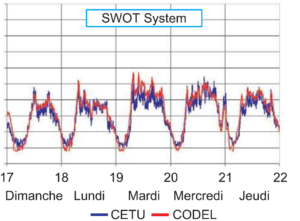

CETU compared the output from the CODEL TunnelTech 205 NO₂ against a chemiluminescence NO/NO₂ analyser in month-long trials. The accompanying chart shows typical 5-days operational periods for each sensor and demonstrates the good agreement of our system against the standard analyser (Chemiluminescence principle is the reference method for NO/NO₂ measurement).

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351