Worldwide Support

Over 25 distributors and support centres worldwide

Flexible maintenance contracts

Tailor made plant specific contracts with 24Hr Support

30 years experience

Developing, manufacturing and installing

Dust Monitoring – Choosing the Right Technology

There are several technologies available to monitor dust emitted from collectors. The traditional ones are based on optical systems. However, sensitivity limitations of optical systems have produced an increased use in tribo-electric probes in modern plant.

Opacity Monitors

These instruments must be used when the required measurement is opacity and are the preferred option for dust density (mg/m³) measurement on almost all schedule ‘A’ processes. To measure dust density, opacity monitors, like all other techniques covered by this publication, require calibration against an iso-kinetic stack test.

The very best opacity monitors can achieve an accuracy of ±0.2% opacity, with more typical performance being in the ±1% to ±2% range. This limits their use on smaller ducts and particularly when dust levels are vey low (0.2% opacity would typically represent 2-4mg/m³ in a 2 metre duct or 4-8mg/m³ in a 1 metre duct). Modern dust collectors achieve very high efficiencies and although opacity monitors are very reliable devices, their sensitivity limitations must be considered when making the choice of monitoring technology.

For indicative monitoring they are rarely the most cost-effective solution as the price range varies significantly depending on the application conditions for why they have been designed.

Back-Scatter Monitors

These instruments project a light into the duct from one side and detect light scattered back from the dust. They are capable of detecting very low levels of dust in small ducts, beyond those required for monitoring most collectors. Critical alignment is not necessary, but they do require air purges to keep their lenses clean. Also, stray light reflecting from the duct causes zero measurement errors. The main draw-back, however, is their higher cost.

Light Modulation Technology

These instruments use a technology known by a variety of names, ‘scintillation’, ‘dynamic transmission’, ‘light modulation’ and ‘flicker’. Essentially, they are similar to opacity meters in that they have two heads, with light being transmitted one to the other. Instead of monitoring the average attenuation of light by the dust particles, these instruments measure only the short-term fluctuations in the transmitted light. They assume that the amplitude of the alternating component, or ‘flicker’ is proportional to the particulate concentration within the stack.

Such instruments are influenced by the degree of turbulence and flow of the gas. Additionally, refraction effects caused by hot turbulent gases can produce significant flicker signals even in totally clean conditions. They are also sensitive to vibration that can induce an interfering alternating component into the signal.

These varied sources of error make the technology unsatisfactory for the measurement of very low dust concentrations.

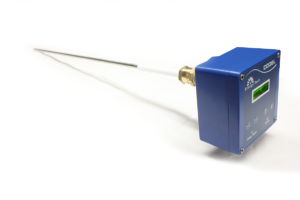

Tribo-Electric Instruments

Dust particles moving through a collection system cause an electrical charge transfer as they strike the inner surfaces of the duct. This results in particles within the gas stream carrying a net electrical charge. A conductive probe inserted into the gas stream will gain charge from these particles as they strike the probe.

Assuming the amount of charge held by a particle is proportional to its mass, the electrical signal developed at the probe (dependent on the rate of charge transfer), will be proportional to the mass flow of dust particles in the gas stream.

The tribo-electric technique is extremely sensitive, capable of detecting dust concentrations of less than 1 mg/m³ in small ducts. These instruments are easy to install, requiring only a simple probe and are ideal for small duct sizes. Minimal maintenance, restricted to infrequent probe cleaning and low installation costs make this technology extremely attractive for dust collector monitoring.

CODEL’s EnergyTech 301 offers a high performance and cost-effective solution for dust monitoring.

Click here to find out more about the EnergyTech 301

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351