Worldwide Support

Over 25 distributors and support centres worldwide

Flexible maintenance contracts

Tailor made plant specific contracts with 24Hr Support

30 years experience

Developing, manufacturing and installing

Enhancing Industrial Safety with Triboelectric Dust Monitoring and Burst Bag Detection

Industrial environments face constant challenges when it comes to air quality, safety, and efficiency. One of the most common risks is dust – invisible to the eye but capable of damaging equipment, contaminating products, and endangering worker health. Effective dust monitoring and burst bag detection are therefore critical for maintaining safe and compliant operations.

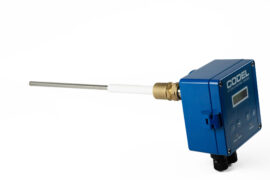

At CODEL, we’ve developed a new range of triboelectric dust monitors designed to deliver accurate, real-time data and reliable baghouse protection. When combined with burst bag detection, these systems provide industries with a complete solution for dust management.

What is a Triboelectric Dust Monitor?

Triboelectric dust monitors measure airborne particulate concentrations using the principle of triboelectricity. As dust particles move through a charged probe, they generate tiny electrical signals that are detected and converted into precise, real-time measurements.

This method makes triboelectric detection one of the most reliable ways to continuously monitor particulate emissions in industrial processes such as power generation, cement, steel, biomass, and waste-to-energy plants.

Key Benefits of Triboelectric Dust Monitoring:

Continuous real-time monitoring – instant detection of abnormal dust levels.

High sensitivity – capable of detecting even very low concentrations.

Low maintenance – simple design with no moving parts.

Regulatory compliance – supports industries in meeting air quality standards.

Integration ready – works seamlessly with control systems for automated responses.

Burst Bag Detection – Protecting Your Baghouse

In dust collection systems, fabric filter bags are widely used to capture airborne particles. However, these filters can fail due to wear, damage, or unexpected bursts. Even a single bag failure can release large amounts of dust into the environment, creating safety hazards, environmental breaches, and costly downtime.

A burst bag detection system instantly alerts operators to bag leaks or failures. Using changes in dust levels, the system triggers alarms or automated safety responses before the issue escalates.

Benefits of Burst Bag Detection:

Early fault detection – take action before a small issue becomes a major problem.

Reduced emissions – prevents dust escaping into the workplace or atmosphere.

Lower maintenance costs – targeted maintenance avoids unnecessary shutdowns.

Improved efficiency – ensures dust collectors perform at maximum effectiveness.

The Power of Integration

When triboelectric dust monitors are combined with burst bag detection, industries gain a complete air quality solution. Together, these technologies provide:

Accurate dust concentration data for compliance and reporting.

Rapid identification of bag failures to prevent costly downtime.

Optimised system efficiency through automated alerts and responses.

Enhanced workplace safety by reducing exposure to harmful particulates.

This integrated approach gives operators the tools they need to protect workers, equipment, and the environment while improving operational performance.

Conclusion

As industries face increasing pressure to maintain safety, efficiency, and environmental compliance, advanced monitoring technologies are no longer optional, they are essential.

CODEL’s new triboelectric dust monitoring range, combined with robust burst bag detection, provides a powerful solution for managing dust emissions in the harshest industrial environments.

By investing in these technologies, companies can reduce risks, cut downtime, and ensure compliance with international air quality standards, all while building a safer and more sustainable future.