Worldwide Support

Over 25 distributors and support centres worldwide

Flexible maintenance contracts

Tailor made plant specific contracts with 24Hr Support

30 years experience

Developing, manufacturing and installing

How Are Dust Collector Systems Monitored?

Operator Visual Checks

Looking at stacks and vents and identifying dust emissions is extremely time consuming, inaccurate and probably too late. When a dust collector starts to leak small amounts of dust, it is impossible to detect with the human eye. If the sky is overcast or it is raining, it becomes even more difficult to pick up dark dust particles. Furthermore, as this is a very subjective measurement, 10 people will give 10 very different assessments.

Unless the dust emitted is pure white (e.g. titanium dioxide) against a dark background, then the minimum levels capable of being detected by the human eye, are quite high. Essentially, by the time it is visible, extreme conditions already exist in the dust collector system. Finally, human assessment is random and usually performed only once a day and then recorded. This is not frequent enough to build up a picture of plant performance and be able to react to serious changes.

Differential Pressure Gauges

These devices measure the difference in pressure between the dirty and clean sides of the filter bags. As the dust cake builds up in the bags, the differential pressure can increase to a high level. If a bag tears, the resistance of the bag is dramatically reduced and the differential pressure drops towards zero.

Continual observation of the differential pressure would detect a leaking filter bag, but in practice this is not usually possible. Generally observed only periodically by an operator, this check may be logged, but rarely is the output continuously recorded.

A major problem with these devices is the frequency with which the pressure tapping on the dirty side of the collector becomes blocked. When this occurs, the collector must be taken offline for removal and cleaning of the pressure gauge.

The main release of dust from a torn filter bag occurs when it is being cleaned. The dust cake is blown off the bag using a short blast of compressed air, and escapes through the tear. As the whole row is being clean simultaneously, the differential pressure drops and this often masks the pressure drop caused by the leaking bag.

Differential pressure devices are not sensitive enough to detect small tears as these cause very little change in pressure.

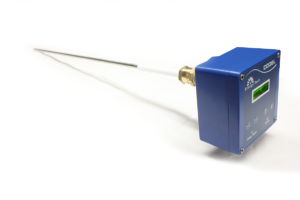

Continuous Dust Monitor

Various instruments are available using different technologies to continuously monitor the emissions from a stack. Some instruments are sensitive enough to detect pin-hole leaks and have an alarm contact to activate an annunciator or a flashing alarm light at a set-point, when leaks occur. Other advanced instruments also have an output to a data logging device, enabling the operator to record emissions. Carefully utilised, this facility will predict leaking bags, enabling the operator to react and prevent critical plant shutdowns.

Some of these instruments react very quickly to changes in dust level and are unaffected by changes in the collector such as differential pressure. The other key feature of these instruments is the extreme sensitivities they can achieve (dependent on the technology) and their wide operating range. For example, the EnergyTech 301 from CODEL can detect levels between 0 and 6500mg/m³ and detect particles as small as 0.1 micron. The technology chosen will depend on the specific legislative requirement and the application conditions. There is no universal solution for all situations.

In the United Kingdom, as in other countries throughout the world, regulators are calling for dust monitors to help reduce harmful emission to atmosphere. Continuous dust monitors are recognised as the only reliable, sensitive and accurate means of monitoring the performance of dust collectors.

Click here for more information.

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351