Worldwide Support

Over 25 distributors and support centres worldwide

Flexible maintenance contracts

Tailor made plant specific contracts with 24Hr Support

30 years experience

Developing, manufacturing and installing

Using a Dust Monitor to Diagnose Potential Problems

Most fabric dust collectors clean their filter bags by injecting a short blast of compressed air down a singe row of bags. This is repeated until every row of bags is cleaned, or until the desired level of differential pressure is achieved. The cleaning sequence is usually by a timer or a differential pressure gauge. When the air has stopped and the dust ‘cake’ removed, the bag becomes momentarily porous and particles rush through the open pores until dust gradually reseals the bag.

This event is seen by the sensor as a ‘spike’ 3 to 4 times the height of the normal dust level. However, if a particular filter bag becomes torn, the spike detected from that row becomes much larger. The row containing the leaking filter bag is found by counting the number of spikes from the beginning of the cleaning sequence.

It is important to set the instrument damping to less than 20 seconds to view the output. If a longer time is set, the spikes become integrated over a longer period and it becomes much harder to pick out leaking filter bags. On some types of filter bags it may take up to 20 seconds for the bags to reseal.

Electro-Static Precipitators

Tribo-electric dust monitors will monitor the dust collector as the efficiency drops. By setting the damping to a low value, say 20 seconds, ‘rapping’ events are identified. This will show how much dust is being emitted during rapping. If the amount of dust is especially low for a particular field, then it follows that it is ineffective and may require attention.

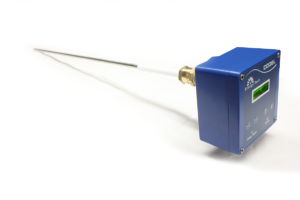

The EnergyTech 301 is a low-cost dust monitor using well proven tribo electric technology providing accurate and rapid results. The EnergyTech 301 requires no critical alignment and has no optical surfaces to keep clean. The sensor is easy to install, requiring only a simple probe and is ideal for small duct sizes.

Click here to find out more

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351