The use of Continuous Emission Monitoring Systems in Steel Mills

Steel mills are known for their intensive manufacturing processes, which generate a range of emissions that are tightly regulated. Continuous Emissions Monitoring Systems (CEMS) are critical for steel mills to ensure compliance with environmental regulations while optimizing production efficiency.

CEMS monitor key pollutants released during steel production, including NOx, SOx, carbon monoxide (CO), and particulate matter (PM). These emissions result from high-temperature combustion and other industrial processes used in steel manufacturing. Continuous monitoring of these emissions allows steel mills to maintain pollutant levels within regulated limits, mitigating their environmental impact. CEMS provide early detection of operational issues that may cause excess emissions in steel mills. This allows real-time adjustments to maintain efficient and compliant steel production operations.

CEMS monitor key pollutants released during steel production, including NOx, SOx, carbon monoxide (CO), and particulate matter (PM). These emissions result from high-temperature combustion and other industrial processes used in steel manufacturing. Continuous monitoring of these emissions allows steel mills to maintain pollutant levels within regulated limits, mitigating their environmental impact. CEMS provide early detection of operational issues that may cause excess emissions in steel mills. This allows real-time adjustments to maintain efficient and compliant steel production operations.

Beyond regulatory compliance, the integration of CEMS into steel mills’ processes helps facilities meet sustainability goals. Controlling emissions helps steel mills avoid costly environmental fines and penalties. It also contributes to cleaner air and improves worker health and safety. The ability to track emissions data over time allows operators to implement better pollution control strategies and optimize their overall environmental footprint.

How CODEL Can Support Steel Mills with Emission Monitoring

CODEL International Ltd. offers advanced emission monitoring systems specifically designed to meet the needs of the steel manufacturing industry. Our CEMS solutions provide reliable, continuous measurement of critical pollutants such as NOx, SOx, CO, and particulate matter, helping steel mills stay compliant with ever-evolving environmental regulations.

Designed for the harsh conditions of steel mills, CODEL’s systems are built to withstand high temperatures, dust, and particulates, ensuring long-lasting performance with minimal maintenance. By offering real-time data and comprehensive reporting, our monitors enable steel mill operators to track emissions continuously, optimize their processes, and make informed decisions to improve operational efficiency. Whether upgrading your existing monitoring systems or installing new ones, CODEL’s emission monitors provide the precision and reliability needed to support the steel industry in reducing emissions and achieving sustainability goals.

Suitable Products

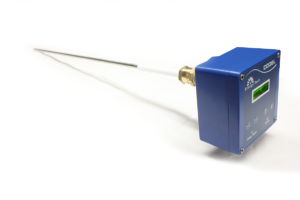

The EnergyTech 301 is a low cost tribo electric dust monitor using well-proven technology providing accurate and rapid results.

Dust

A single-pass optical device which uses visible light to measure the opacity and dust within the flue gas.

Opacity / Dust

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351